(Standard disclaimer - despite my good looks and brains, I cannot make you do anything. You are responsible for your own actions including deciding whether or not you are capable of performing any DIY work on cars - yours or others. Attempting to do what I describe in this post will probably wreck something, so I will not be held responsible for any damage to you, your car or anything else I don't actually touch with my own fingers.)

Over at the Yaris Forum is a bunch of excellent articles that show what to do. I stumbled across them a couple years ago, but waited until the warranty had essentially run out before mucking with the electronics.

My car has the power option (power locks / windows), this means all the wiring harnesses are pre-installed and ready to go. The only real cost I had was the clutch switch. That was $35 plus taxes from my local dealership. I could have done without, but if the driver would press the clutch with the cruise engaged, the engine would rev up (hopefully limited by the computer) and would present a danger should the clutch be re-engaged at high RPMs. So that is where I will start, crawling under the dash, on my head to install the clutch switch.

It replaces the bolt, and like I said, all the harnesses are installed already, so I just had to cut some electrical tape to free the clutch switch harness and plug it in.

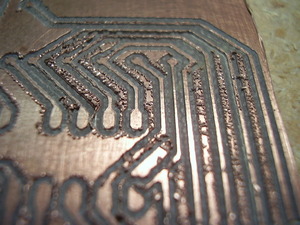

Next came installing the switch(es). I opted not to purchase the cruise control dongle as a) it is expensive, b) it involves removing the steering wheel (and dealing with the airbag) and c) it is not needed as you will see. The wiring to the steering wheel is in place, so all I had to do was splice into the right wires.

In the original article, the author uses multiple momentary, normally open, push button switches for the various functions. Since I need just On and Set, I opted for a dual throw, momentary toggle switch. I located my switch just below the turn signal switch as that is where there was room.

(I had to trim some plastic ribs to get the switch to mount flush)

Up turns the cruise on/off, down sets the speed (or reduces it by little bit if already engaged).

Yay! It works! Adding cruise to a manual transmission 2012 Yaris is a $530 upgrade. I did it for under $50. (BTW, I live in Canada, so that's 100km/h showing on the speedometer.)