Canadian Tire of all places sells a must have tool for electric RC builders and pilots. A DC current meter that can measure over 10A. This is a clamp style meter (funny that the site calls is a Clap meter). It retails for $59.99 which is decent enough, but this week it went on sale for $20.99!!! Less than $25 taxes in gets a tool that can measure up to 400A of DC current! (BTW, it needs 2 x AAA batteries - the first time I've bought a meter that did not include batteries...)

I saw Mark from Cellar Dweller use one about a year ago to balance the up / down thrust of an electric heli and it immediately went to the top of my wish list.

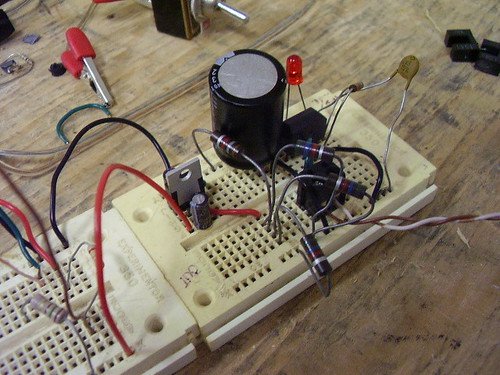

So I just picked one up tonight and tried it out. It's no bazillion dollar Fluke(tm), but for $21 it works quite well. Measured the current draw on one of my planes @ 13.6A (11.1V - 150Watts!). (I think I saw a 16A on the first test, but too much stuff was blowing around the shop, and the battery in the plane was not fully charged.)

One a side by side test with an inline current meter (also Mastercraft), the inline measured 3.08A and the clap :-) meter measured 3.2A.

AC current test was measured while my furnace was running. The reference meter was a cheap (picked up on sale for less than $15 taxes in) PowerFist (Princess Auto) AC clamp current meter. It read 40.1A while the Mastercraft read 38.9A.

That's acceptable tolerance for my needs.

I saw Mark from Cellar Dweller use one about a year ago to balance the up / down thrust of an electric heli and it immediately went to the top of my wish list.

So I just picked one up tonight and tried it out. It's no bazillion dollar Fluke(tm), but for $21 it works quite well. Measured the current draw on one of my planes @ 13.6A (11.1V - 150Watts!). (I think I saw a 16A on the first test, but too much stuff was blowing around the shop, and the battery in the plane was not fully charged.)

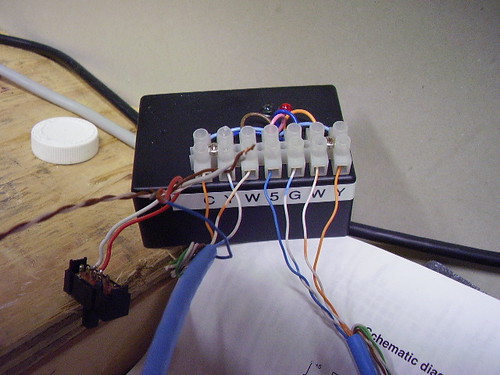

One a side by side test with an inline current meter (also Mastercraft), the inline measured 3.08A and the clap :-) meter measured 3.2A.

AC current test was measured while my furnace was running. The reference meter was a cheap (picked up on sale for less than $15 taxes in) PowerFist (Princess Auto) AC clamp current meter. It read 40.1A while the Mastercraft read 38.9A.

That's acceptable tolerance for my needs.